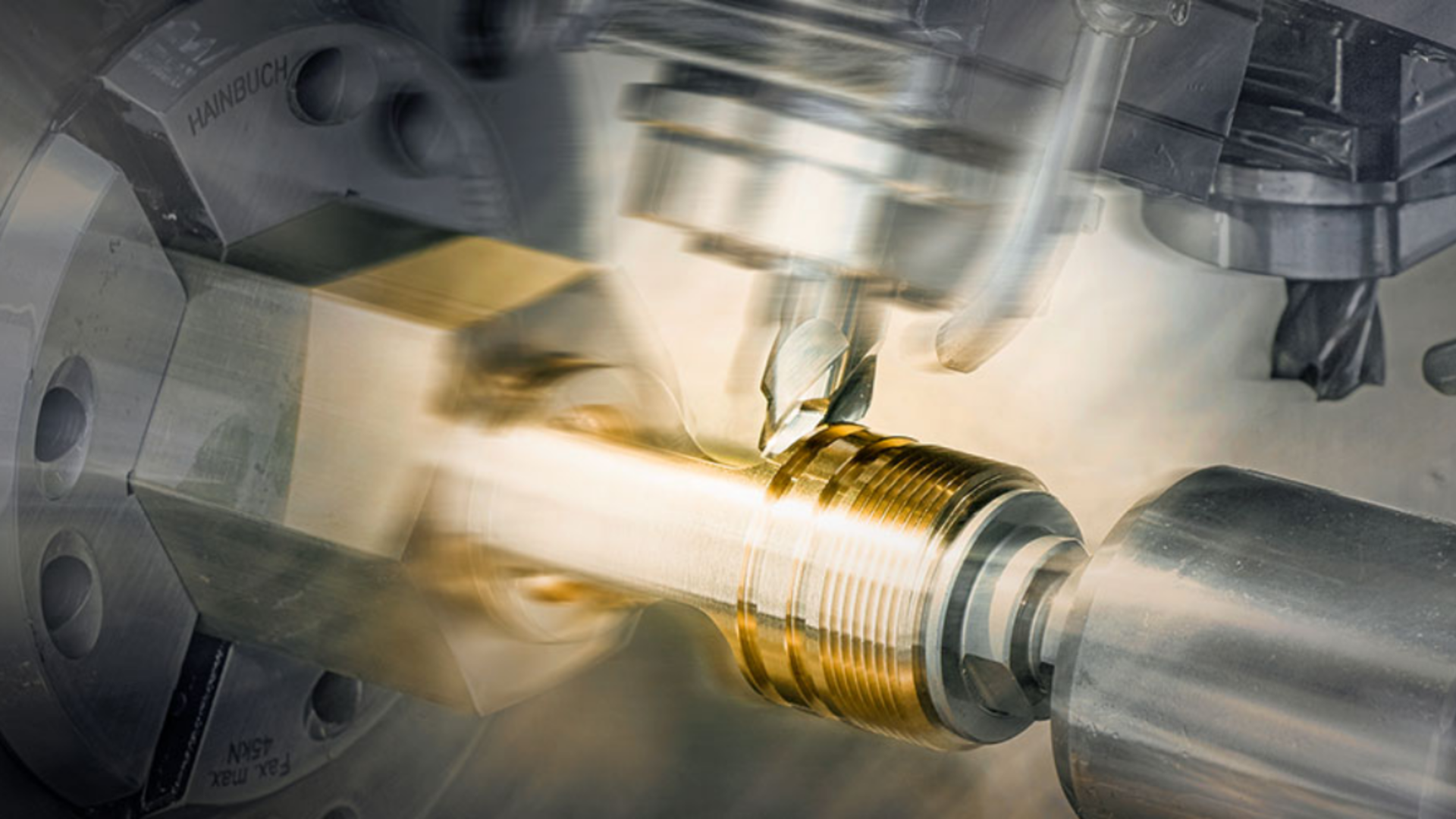

LEAD FREE AND LOW-LEAD ALLOYS

ALWAYS UP TO DATE – QUICKLY AND SUCCESSFULLY

What is the big disadvantage of lead alloys? According to the latest REACH and RoHs directives, the lead content in the materials used should or must be reduced to 0% for many industrial sectors in the coming years. Truly a challenge for all those involved. Thanks to close contact with renowned producers, Manometal is one of the first to test new, lead-free alloys and conduct the first chipping attempts. Internal tests, the technical development of machines and processing tools, and last but not least, the willingness to learn of our employees have made us able to meet market requirements in the processing of even long-chip alloys and achieve very good results.

So, what are CR724r, Ecobrass or Cuphin? Are lead-free alloys able to meet the usual quality standards? Our experience has shown us that it is possible! Soon enough, the new, lead-free alloys will replace common alloys like the CW514n or CW617n.

Manometal is the right partner for switching to unleaded turned parts!