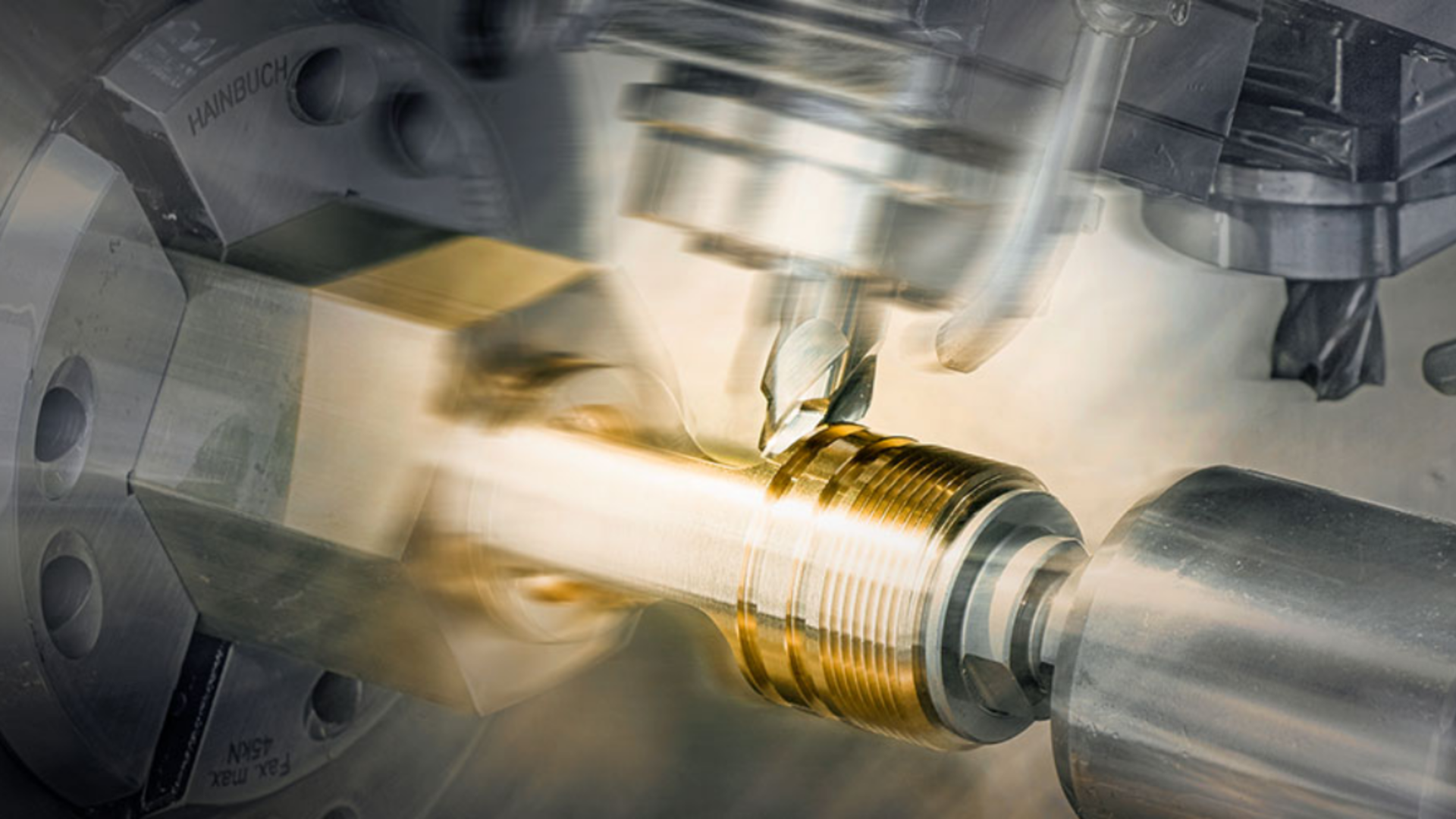

Production engineer | CNC programmer

The job of Production engineer at Manometal comprises the preparation, equipping and monitoring of the individual CNC turning lathes. Independent working is required and various process steps are involved, from drawing to series production release. Other activities include the maintenance and care of the individual production machines.