- Personal exchange

- Advice and proposed solutions

- Offer

What makes us different

WHAT WE LOVE

Quality

-

Test planning for all production steps

-

Observance of the specified tolerance ranges

-

Evaluation of SPC monitoring available on request

-

Consideration of nature and the environment

- Test planning for all production steps

- Observance of the specified tolerance ranges

- Evaluation of SPC monitoring available on request

- Consideration of nature and the environment

Flexibility

-

Customer proximity

-

Streamlined, competent organisation and contact persons

-

Latest production planning with real-time data collection

-

Hard-working, experienced, long-standing, competent and extremely reliable employees

- Customer proximity

- Streamlined, competent organisation and contact persons

- Latest production planning with real-time data collection

- Hard-working, experienced, long-standing, competent and extremely reliable employees

Expert knowledge & performance

-

Extensive experience

-

Friendly and pleasant working environment

-

Constant further training of our employees

-

Planning and implementation of continuous improvement processes

-

Investment in the latest turning production, testing facilities and testing equipment

- Extensive experience

- Friendly and pleasant working environment

- Constant further training of our employees

- Planning and implementation of continuous improvement processes

- Investment in the latest turning production, testing facilities and testing equipment

Deadline reliability & logistics

-

Reliable software, linked to every working process

-

Long-standing, competent shipping partners

-

Finished parts warehouse operated according to FIFO

-

Adaptation to various logistical preferences

-

Day-specific delivery – even within 24h

- Reliable software, linked to every working process

- Long-standing, competent shipping partners

- Finished parts warehouse operated according to FIFO

- Adaptation to various logistical preferences

- Day-specific delivery – even within 24h

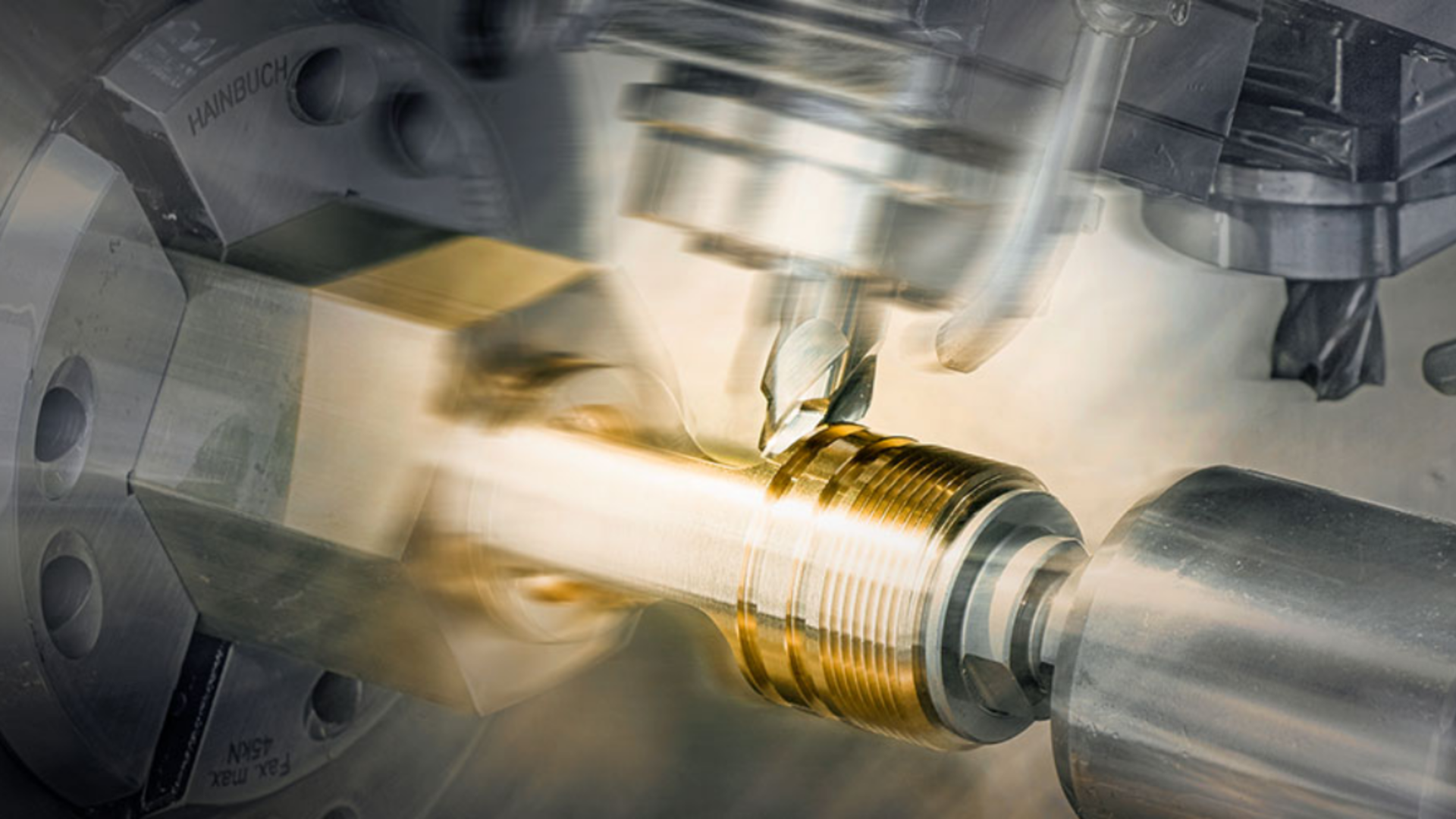

The turning shop from South Tyrol

MANOMETAL – A STRONG PARTNER FOR THE FUTURE

Manometal is one of Italy’s leading automatic turning shops and benefits from its procurement-friendly location on the Italian market and its geographical location in South Tyrol – next to the north-south axis of the Brenner motorway – in German-speaking and multilingual South Tyrol.

The entire production of finished and turned parts is monitored using the latest SPC technology and, by continually controlling processing capability, achieves the goal of delivering faultless parts to the customer.

Production processes are continually improved. Our strengths are perfect surfaces, runout-free and true-to-gauge threads, with or without galvanic surfaces, packaged in value-preserving and protective packaging.

Manometal is at the cutting edge of production with constant internal development of the turned parts production. This way, we are able to deliver the most modern products that respect the latest rules and regulations. As a result, expensive and time-consuming incoming goods inspections by the customer are largely redundant. For example, in the field of alloys, unleaded alloys are playing an increasing role, due to the imminent ban on using lead-containing alloys in different sectors of production. Manometal already has a multi-year experience in the production of unleaded turned parts of the best quality.

To optimise the whole order processing, including the observerance of delivery dates and logistics, Manometal uses a software package that is constantly updated. Once feasibility studies have been completed, all enquiries can be accessed at all times. The entire process, from incoming orders to punctual delivery by international shipping, is therefore in careful, competent hands.