- Personal exchange

- Advice and proposed solutions

- Offer

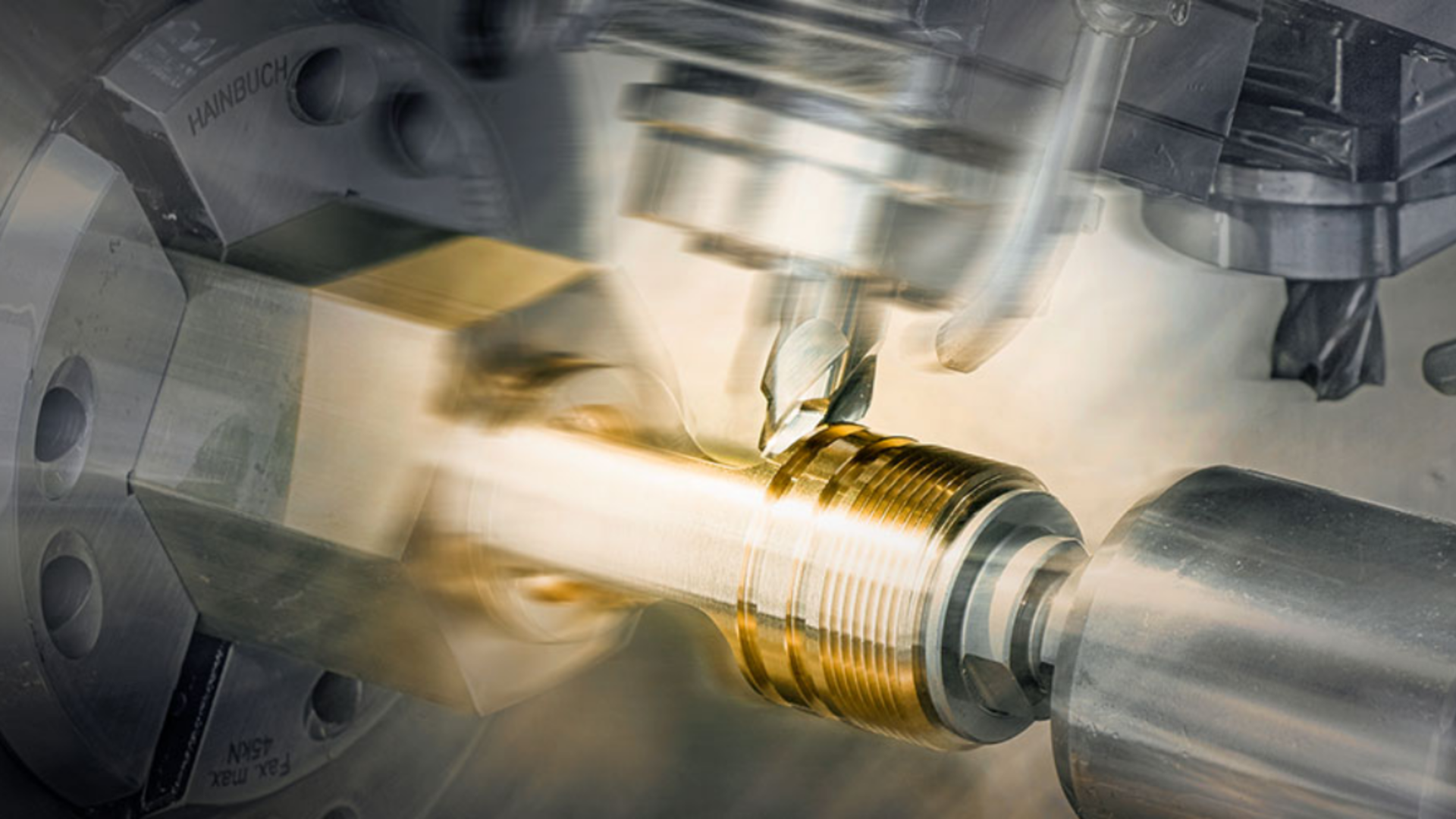

Machinery

OUR PRIDE AND JOY

The series production of precise, drawing-compliant and challenging turned parts in a wide range of alloys requires the use of the latest technologies and a great deal of experience from our employees. In order to meet the requirements of continuous demand, Manometal invests in the latest CNC automatic lathes as well as in testing equipment and production facilities.

Our production strategy is characterised by perfect surfaces and their handling from the machine to automatic and gentle washing processes, right through to protective packaging and warehousing.

Thanks to various production terminals to assemble components, for packaging and other additional work, Manometal offers its customers a complete logistics system with corresponding warehousing capacities for necessary scheduled call orders and safety stocks.

Our machinery is constantly updated to keep up with the latest developments. Right now, it is used more and more to produce unleaded turned parts made from unleaded alloys. This is because the RoHS directive is going to prohibit the use of leaded alloys in more and more sectors in the upcoming years. What has started with the desire to use lead free pipes, is now a trend spanning many different industries. We are proud to offer our clients lead free-compliant products.